Revolutionizing the quality control of white fish

After 17 years of research, Maritech Eye™ is a reality.

Objective quality scan

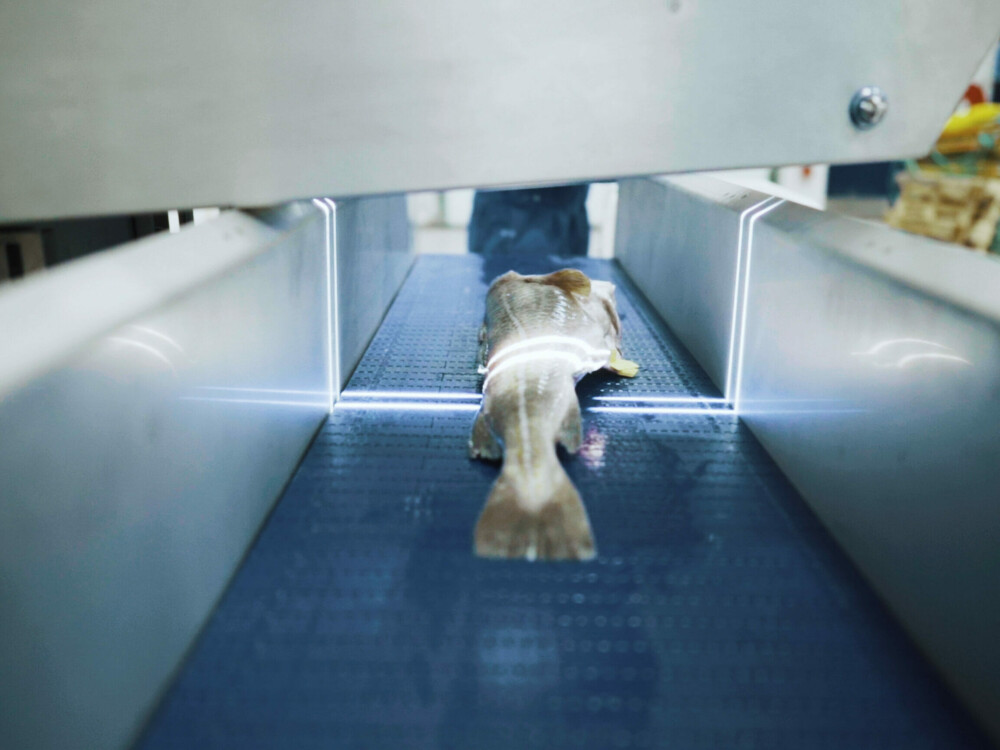

For the first time, fish producers can now determine whether they have caught world-class whitefish even before the fish is gutted.

On Monday 23 November, Maritech, research institute Nofima and Norsk Elektro Optikk (NEO) together with industrial partners Lerøy Norway Seafood and Lerøy Havfisk, proudly announced the launch of a new hyper-spectral camera solution Maritech Eye™– an innovation that may revolutionize the seafood industry. Hyper-spectral camera technology and complex algorithms now makes it possible to run automated, objective quality inspection of whole white fish, at industrial speed.

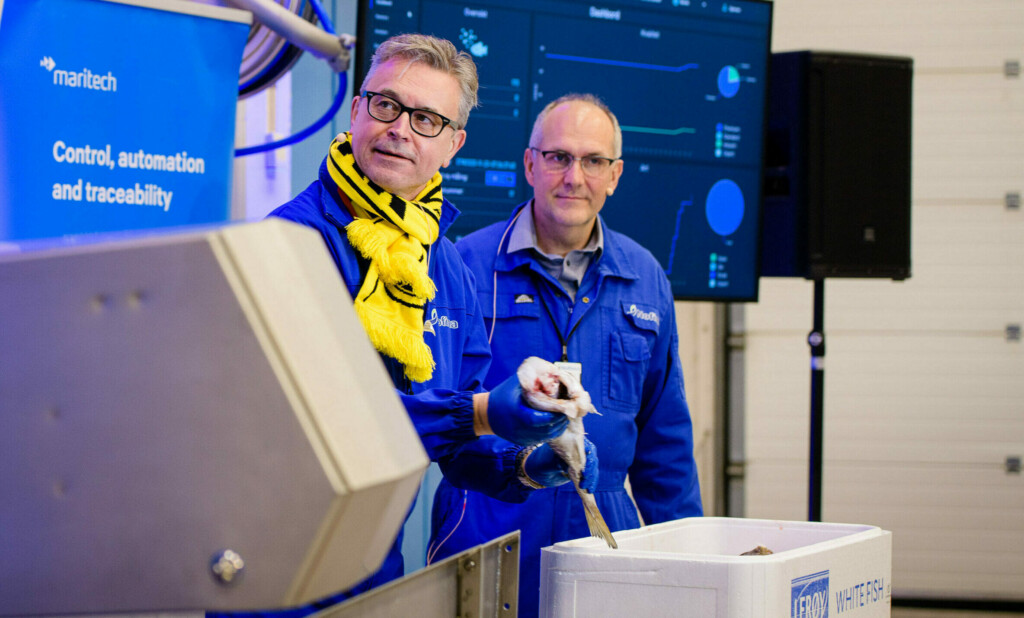

The Norwegian Minister of Fisheries and Seafood, Odd Emil Ingebrigtsen, kicked off the official launch by sending the first fish through the machine that can identify the fish’s quality seeing through its skin.

“This is a great day! A day of champions in several ways”, said an excited Minister of Fisheries and Seafood, who – donning the yellow and black Bodø/Glimt football scarf – also celebrated his regional team´s recent football league championship win.

He said the people who developed the new quality inspection technology also had every reason to celebrate as champions this Monday.

”This project is a prime example of the possible achievements when the business and research communities collaborate on technical innovations. Better quality sorting will increase profitability and the reputation of the seafood industry”, said Ingebrigtsen.

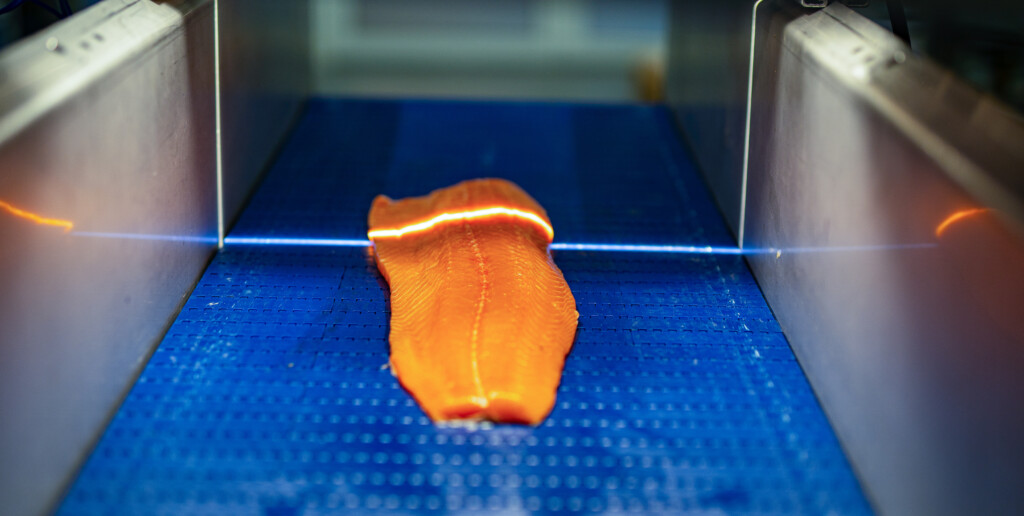

In 2021, Maritech has also been launched for red fish – read more here.

Background

- Maritech has been leading the innovation project and is the commercial provider of Maritech Eye™.

- For 16 years, Nofima Senior Researcher Karsten Heia has collaborated with technology developers in NEO (Norsk Elektro Optikk) who have developed a hyperspectral camera for quality measurements of round fish.

- The industrial trial was carried out at Lerøy Norway Seafoods’ Båtsfjord facility in Finnmark, Norway.

- Maritech Eye™ is now also being tested on board the ocean-going fishing vessels of Norway’s largest trawler company, Lerøy Havfisk AS.

More consistent quality

Maritech Eye™ is the result of the KVASS research project on the quality measurement of whitefish through analysis of spectral images in real time. A business-led project funded by the Fishery and Aquaculture Industry Research Fund (FHF).

The project partners have great expectations for the impact of the machine in the industry.

“Lerøy works every day to raise the quality at all levels of our production of high-quality seafood. With this project, Lerøy has contributed to the development of a technology that provides a better and more consistent raw material quality, which in turn delivers seafood of an even higher quality to our customers,” says Roy Martin Martinsen, Quality Manager for whitefish as a raw material in Lerøy Norway Seafoods. “The intention is that Maritech Eye™ can be implemented in a process line and also contribute to a more efficient production by sorting the raw material based on different qualities in a fish grader” says Martinsen.

Currently the imaging spectroscopy technology is able to detect blood accumulation in ungutted (whole) fish. Roy Martin Martinsen expects that this technology will be developed further to allow the industry in the future to assess even more quality parameters and become even better equipped to deliver quality seafood to consumers.

Are you curious?

We would love to talk to you

Sorting the catch onboard

Lerøy Havfisk AS is Norway’s largest trawler company with ten vessels and 29.6 trawler licences for cod. “In recent years, the company has placed a great emphasis on raising the quality of trawl-caught fish,” says Operations Manager Odd Johan Fladmark. He looks forward to using the new tool in this work.

“With this equipment, we now see the possibility of being able to better sort the catch on board based on quality, which makes it possible for us to offer a fully sorted raw material which is in line with the scanner’s objective. We believe this will give us a better price for the fish and improve profitability for the onshore facilities”, says Fladmark.

Stronger reputation

Those who have worked on the development of the technology are also hopeful and proud to have participated in a historical industrial innovation project, and expect to see a significant impact on the industry.

Maritech has worked closely with both scientists and the industry to develop the solution, and is very pleased with the result.

“This project excited me due to the possibilities which the objective quality measurements of the total volume of fish passing through the production lines provide us with in terms of a) analyses for uncovering possible process improvements and b) correct utilization of raw material based on its quality. And of course – the possibilities for optimizing factory operations”, says Odd Arne Kristengård, CEO of Maritech.

He points out that the associated reduction in wastage and quality complaints will result in increased profitability and sustainability. “Maritech Eye™ represents a significant competitive advantage which may transform the entire industry as well as help boost the reputation of Norwegian seafood exports further”, says Kristengård.

World leader

Trond Løke is the CEO of Norsk Elektro Optikk AS, which has been developing hyperspectral cameras (HySpex) since the early 2000s and is currently collaborating with prestigious Norwegian and international research communities.

“Nofima was our very first client and bought their first hyperspectral camera in 2003. I find it particularly enjoyable that, together with Maritech and in collaboration with Lerøy and Havfisk, we have now developed a complete commercial product which will revolutionize the quality control process for whitefish. For NEO it’s an extra feather in our cap that the fishing industry, a cornerstone of Norwegian industries, is among the first in the country to seriously take advantage of the hi-tech solution hyperspectral cameras represent. In this field we are actually world leaders”, says Trond Løke.

Proud and excited scientist

Without Nofima scientist Karsten Heia, the solution that was launched on Monday would never have seen the light of day. He has been working on developing this technology for decades. The first time he attempted to measure the quality of fish by using imaging spectroscopy was in 1997. Back then it took half an hour to inspect a 10 x 10 cm skin-free piece of fish. Now, the solution can assess whole fish with skin at industrial speed.

“Today I am both a proud and excited scientist. Being able to utilize imaging spectroscopy in an industrial setting is a major milestone for me as a scientist, for Nofima as a research institute and for the Norwegian fishing industry. The fact that we, as an institute for applied research, using funding from the FHF, can contribute to uplifting the Norwegian business community in terms of both technological developments and innovations in the food industry, is a big deal”, says Karsten Heia.

Curious to learn more? Let us know!

Images: Lars Åke Andersen/Frifoto